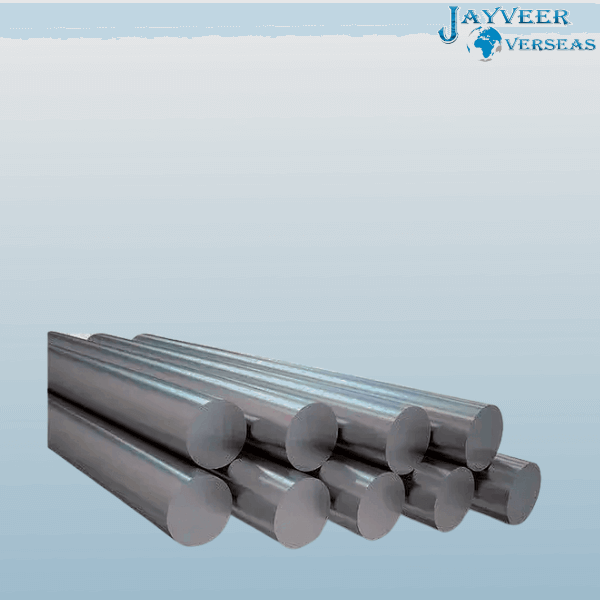

UNS S31803 Round Bar

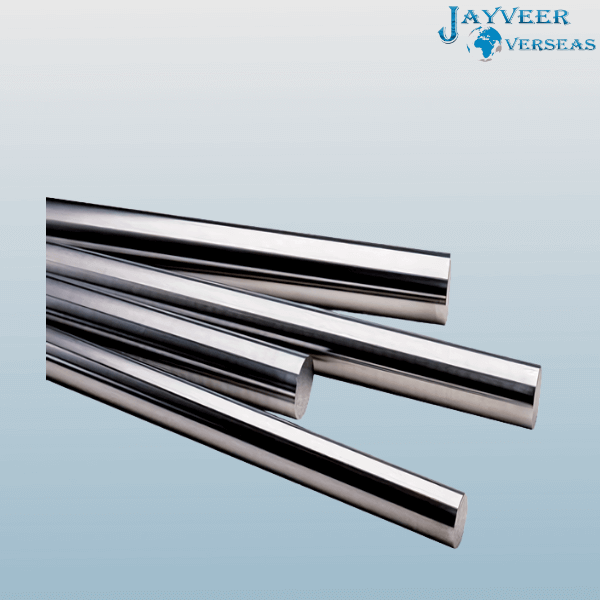

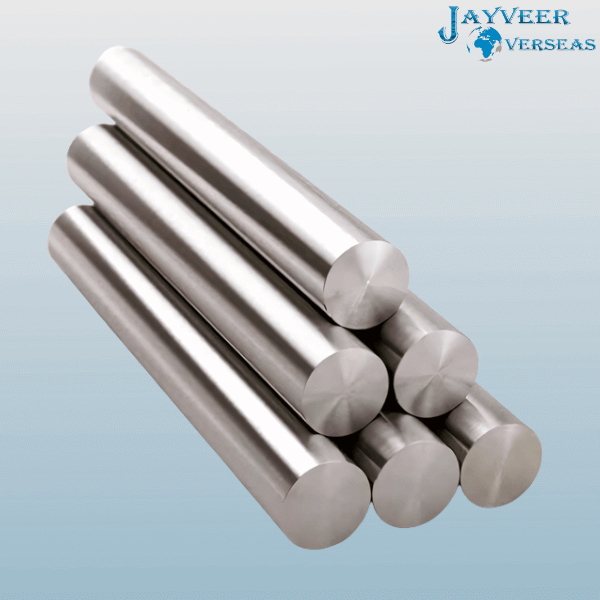

Jayveer Overseas have Premium quality of UNS S31803 Round Bar in various size and dimension, We are manufacturer and supplier in all over India. Due to the variety of qualities that duplex stainless steel round bars may provide, they are preferred. The round bars resist fatigue, have a high energy absorption capacity, and low thermal expansion. Additionally, it guarantees strong mechanical strength and great weldability. Processing this alloy is difficult since it contains alloying elements, including nickel, nitrogen, chromium, and molybdenum.

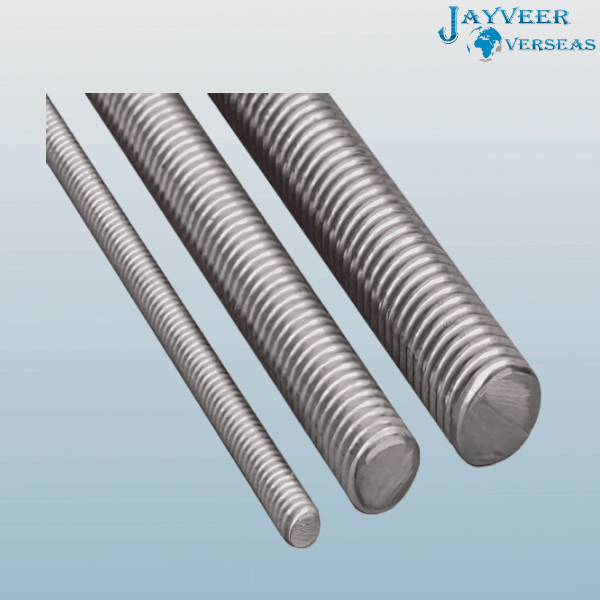

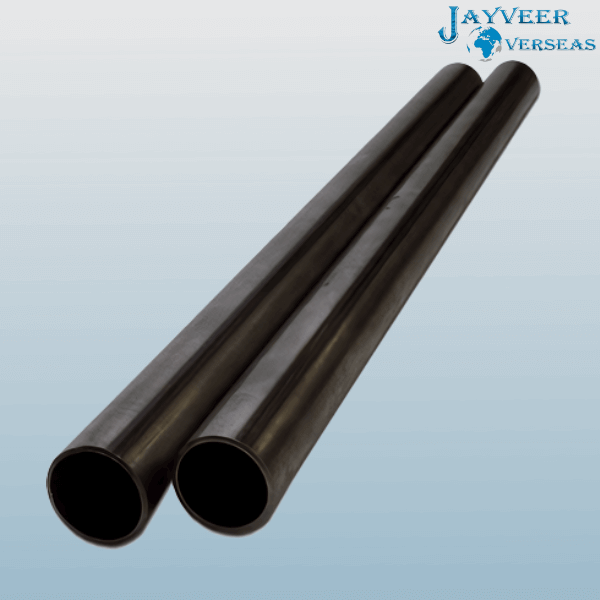

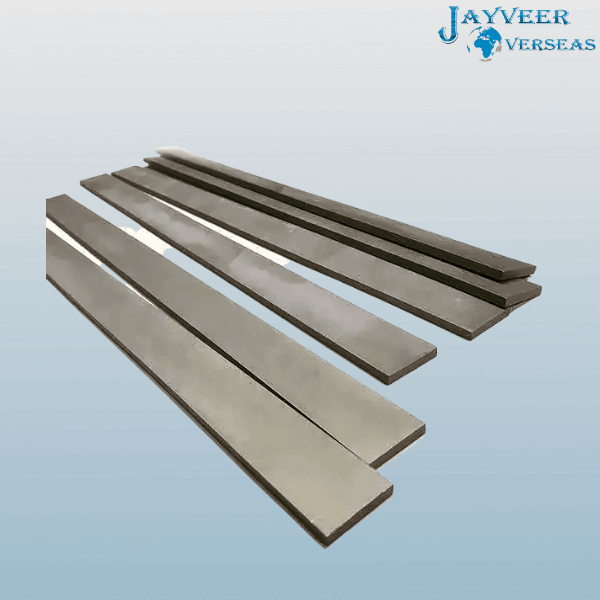

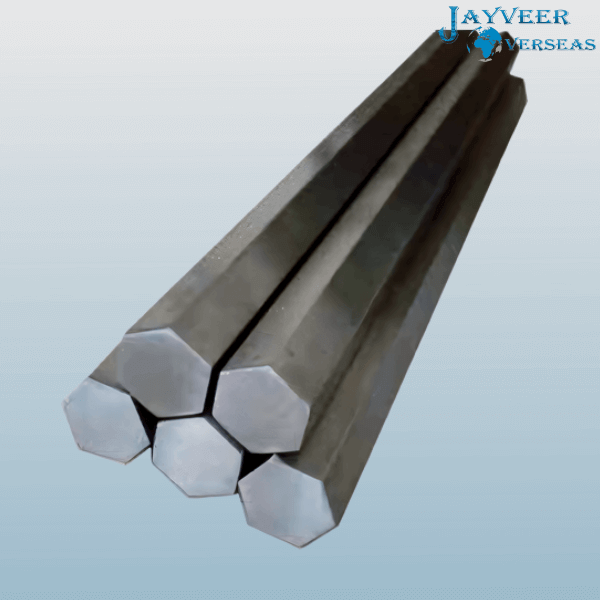

Duplex S331803 Square Bar, DIN 1.4462 Black Bar, ASTM A276 Type Duplex 31803 Bright Bar, Duplex Steel 31803 Hex Bar, UNS S31803 Threaded Bar, Duplex 31803 Rectangular Bar, ASME SA479 Duplex 31803 Cold Drawn Bar.

The material is heated during processes like welding, which causes the precipitation of intermetallic phases. These round bars are ideal for high-corrosion settings, which is why they are employed in onshore, offshore, and marine applications. Since it resists breaking easily and may be used in high-pressure circumstances, this material is more suitable for the residential and commercial sectors.

The outside diameter of the circular bars ranges from 4mm to 500mm. These round bars’ physical characteristics include a density of 7805 kg/m3 and a melting range of 1450–1510 °C. Modules of Elasticity, which have a value of 28 x 106, and the tensile strength at which the material breaks, which has a value of 670 Mpa, are two mechanical characteristics of this round bar. The Round Bars’ overall corrosion resistance and creep potency at high temperatures have increased. The bars feature a classy finish in either BA Finish, Matt Finish, Rough Turned, or Bright Polish. These round bars have a 25% elongation and an MPA-450 yield strength. The tolerance of these round bars vary according to the requirements. The surface of these rods also changes according to the requirements. They can be in the form of hairline, polished or cold drawn. The environment condition under which these bars are manufactured are annealed and tempered. Several testslike material test, pitting corrosion test and intergranual corrosion test are also been performed on these materials yo check its durability, robustness and strength. Duplex steel rods have excellent, consistent corrosion and pitting resistance, high strength, and strong stress corrosion cracking resistance (SCC). Industries provide these round bars and rods to a variety of industries, such as sugar mills and distilleries, cement manufacturing, shipbuilding, oil and gas equipment, paper and pulp, offshore technology, seawater desalination plants, oil and gas equipment, offshore technology, chemical and food processing, and petrochemicals.

UNS S31803 Hexagonal Bar Exporter, DIN 1.4462 Polished Bar Manufacturer, Duplex Steel 31803 Flat Bar Exporter, UNS S31803 Half Round Bar Supplier, Duplex 31803 Triangle Bar Stockist, DIN 1.4462 Deformed Bar Supplier, ASTM A276 Duplex 31803 Hot Rolled Bar Stockist, Duplex 31803 Peeled Round Bar Supplier.

Specification:- UNS S31803 Round Bar

| Specifications | ASTM A276, A479 / ASME SA276, SA479 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars | 18mm – 57mm (11/16″ to 2-3/4″) |

| Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

| Flat Bars | 1/2” to 10” in thickness range of 2mm to 150mm, |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

Equivalent Grade :- UNS S31803 Round Bar

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex S31803 | 1.4462 | S31803 |

Chemical Composition :- UNS S31803 Round Bar

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

Mechanical Properties :- UNS S31803 Round Bar

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Dimensions :- UNS S31803 Round Bar

| Diameter or Width (mm) | Weight per meter | Sectional Area | Perimeter | |||

| Square (kg) | Round (kg) | Square (cm²) | Round (cm²) | Square (cm) | Round (cm) | |

| 5.0 | 0.20 | 0.15 | 0.25 | 0.20 | 2.0 | 1.57 |

| 5.5 | 0.24 | 0.19 | 0.30 | 0.24 | 2.2 | 1.78 |

| 6.0 | 0.28 | 0.22 | 0.36 | 0.28 | 2.4 | 1.88 |

| 7.0 | 0.38 | 0.30 | 0.49 | 0.38 | 2.8 | 2.20 |

| 8.0 | 0.50 | 0.39 | 0.64 | 0.50 | 3.2 | 2.51 |

| 9.0 | 0.64 | 0.50 | 0.81 | 0.64 | 3.6 | 2.83 |

| 10 | 0.73 | 0.63 | 1.00 | 0.79 | 4.0 | 3.14 |

| 11 | 0.95 | 0.75 | 1.21 | 0.95 | 4.4 | 3.46 |

| 12 | 1.13 | 0.89 | 1.44 | 1.13 | 4.8 | 3.77 |

| 14 | 1.54 | 1.21 | 1.96 | 1.54 | 5.6 | 4.40 |

| 16 | 2.01 | 1.58 | 2.56 | 2.01 | 6.4 | 5.03 |

| 18 | 2.54 | 2.00 | 3.24 | 2.54 | 7.2 | 5.65 |

| 20 | 3.14 | 2.47 | 4.00 | 3.14 | 8.0 | 6.28 |

| 22 | 3.80 | 2.98 | 4.84 | 3.80 | 8.8 | 6.91 |

| 25 | 4.91 | 3.85 | 6.25 | 4.91 | 10.0 | 7.85 |

| 28 | 6.15 | 4.83 | 7.84 | 6.16 | 11.2 | 8.80 |

| 32 | 8.04 | 6.31 | 10.24 | 8.04 | 12.8 | 10.05 |

| 36 | 10.17 | 7.99 | 12.96 | 10.18 | 14.4 | 11.31 |

| 40 | 12.56 | 9.86 | 16.00 | 12.57 | 16.0 | 12.57 |

| 45 | 15.90 | 12.49 | 20.25 | 15.90 | 18.0 | 14.14 |

| 50 | 19.62 | 15.41 | 25.00 | 19.64 | 20.0 | 15.71 |

| 56 | 24.62 | 19.34 | 31.36 | 24.63 | 22.4 | 17.59 |

| 63 | 31.16 | 24.47 | 36.69 | 31.17 | 25.2 | 19.79 |

| 71 | 39.57 | 31.08 | 50.41 | 39.59 | 28.4 | 22.31 |

| 80 | 50.24 | 39.46 | 64.00 | 50.27 | 32.0 | 25.13 |

Types :- UNS S31803 Round Bar

weight chart :- UNS S31803 Round Bar

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3" | 10.900 | 35.762 |

| 1/8" | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4" | 12.800 | 41.996 |

| 5/32" | 0.029 | 0.095 | 7/8" | 0.926 | 3.038 | 3-1/2" | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4" | 17.001 | 55.780 |

| 3/16" | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4" | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1" | 1.210 | 3.970 | 4-1/4" | 21.908 | 72.249 |

| 7/32" | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2" | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4" | 27.366 | 90.249 |

| 1/4" | 0.076 | 0.249 | 1-1/8" | 1.534 | 5.033 | 5" | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2" | 36.690 | 121.000 |

| 5/16" | 0.118 | 0.387 | 1-1/4" | 1.924 | 6.349 | 6" | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2" | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8" | 2.303 | 7.550 | 7" | 59.432 | 196.000 |

| 3/8" | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2" | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8" | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10" | 121.048 | 397.140 |

| 7/16" | 0.232 | 0.761 | 1-1/2" | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2" | 0.303 | 0.994 | 1-5/8" | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4" | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16" | 0.383 | 1.256 | 1-7/8" | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8" | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2" | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8" | 5.475 | 17.963 | |||

| 11/16" | 0.573 | 1.880 | 2-1/4" | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4" | 0.682 | 2.237 | 2-3/8" | 6.838 | 22.435 | |||

| 2-1/2" | 7.576 | 24.856 | ||||||

| 2-5/8" | 8.354 | 27.409 | ||||||

| 2-3/4" | 9.169 | 30.083 |

available stocks :- UNS S31803 Round Bar

Price List :- UNS S31803 Round Bar

| Round Bars | US $1000-2500 / Ton |

| Square Bars | US $1000-2500 / Ton |

| Flat Bars | US $1.5-4.5 / Kilogram |

| Threaded Bars | US $1800-2300 / Ton |

| Hollow Bars | US $1550-2400 / Ton |

| Hexagonal Bars | US $1800-2300 / Ton |

| Triangular Bars | US $1300-2600 / Metric Ton |

industries we serve :

- Biodiesel and ethanol plants and tanks

- Palm oil and wine storage tanks

- Bridges, flood gates, and sluice gates

- Washers and paper machine parts

- Pulp and paper mill equipment

- Mixers and agitators

- Architectural applications

- Waste water handling systems

- Ethanol production components

- Desalination system chambers and evaporators

- External absorber and outlet duct reinforcements

- Chemical process pressure vessels, piping and heat exchangers

- Pressure vessels, heat exchangers, tanks, piping systems and tankers

- Hydrogen peroxide bleaching reactors, digesters, and white liquor storage tanks

Packaging Used by us :

We ship our stainless steel metal products in industry leading packaging designed to ensure your order reaches its destination safely. We offer multiple packaging options to meet your specific requirements. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging. We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

- Shrink-wrapped

- Carton boxes

- Wooden pallets

- Wooden boxes

- Wooden crates

Quality and tests Done by us :

- Positive material recognition

- Mechanical examining like tensile, Elongation and reduction of area.

- Large-scale test

- Chemical examination-Spectro analysis

- Firmness test

- Pitting protection test

- Hydrogen-effected cracking test approved by NACE TM0284

- Small tests

- X-ray test

- Impact analysis

- Eddy current examining

- Hydrostatic analysis

- Prompt test

- Sulfide stress corrosion test approved by NACE TM 0177

- Curve test

-

Related Search Queries

-

City We Supply

-

Country We Export