CU NI 90-10 Round Bar

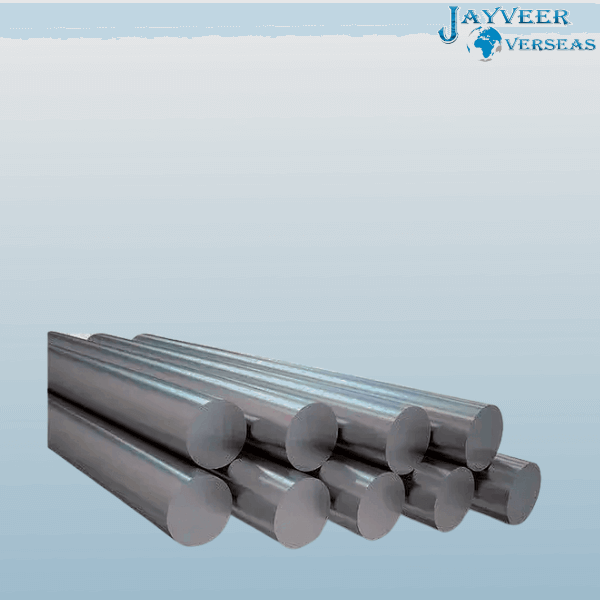

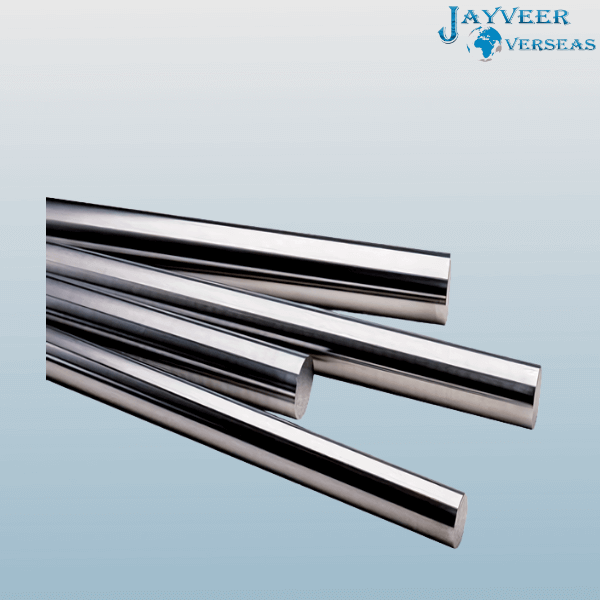

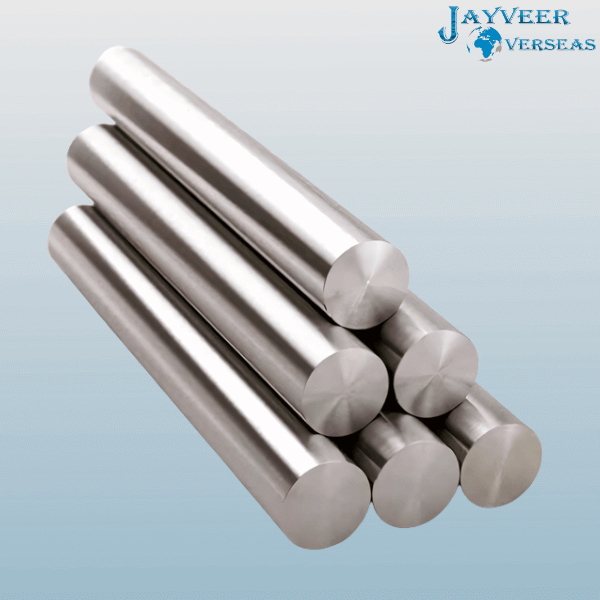

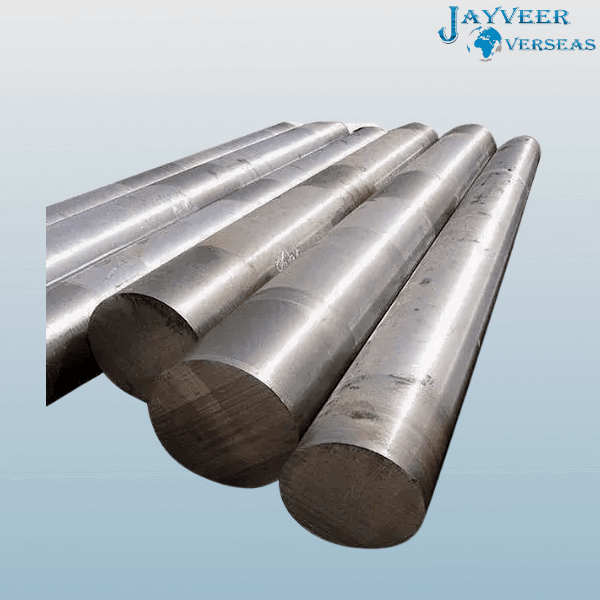

Jayveer Overseas are one of the leading Manufacturers, Supplier and Exporters of best quality CuNi 90-10 round bar in Mumbai, India. We offering high-grade Stainless Steel round bar at the most reasonable prices. The copper-nickel 90/10 round bars contain elements like copper, nickel, and iron. They are made in the austenitic form. When producing Cu Ni 90/10 Round Bars, 90% of the metal is copper, and 10% is nickel. It also has some manganese and iron content, improving its exceptional corrosion resistance and tensile strength. As a result, it has several positive characteristics, including strong resistance to erosion and stress corrosion.

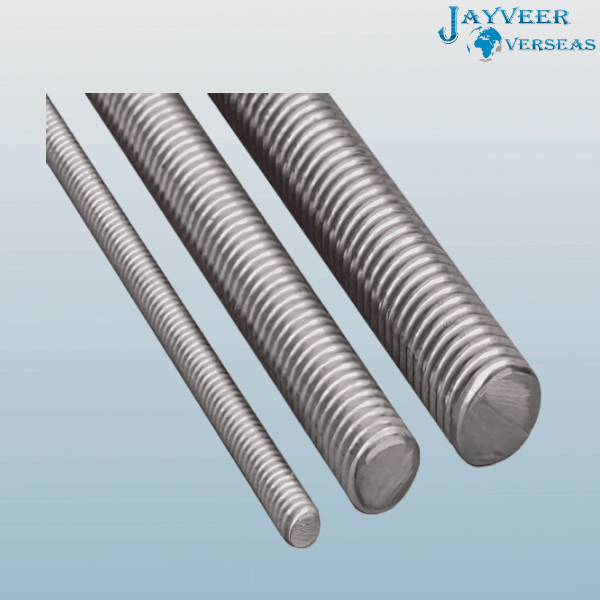

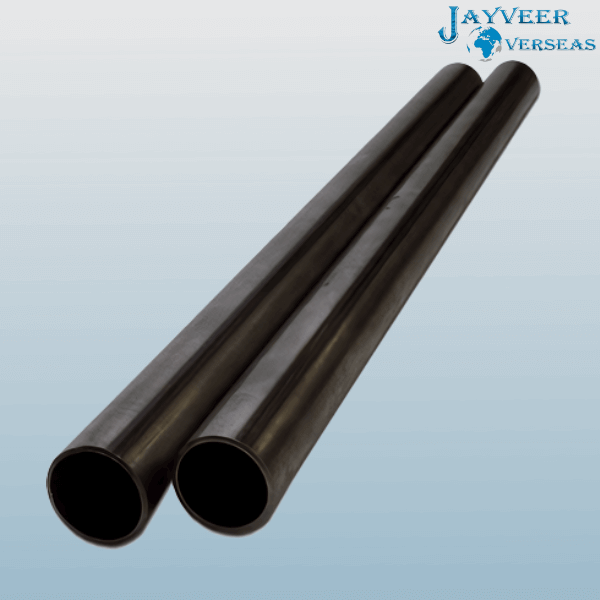

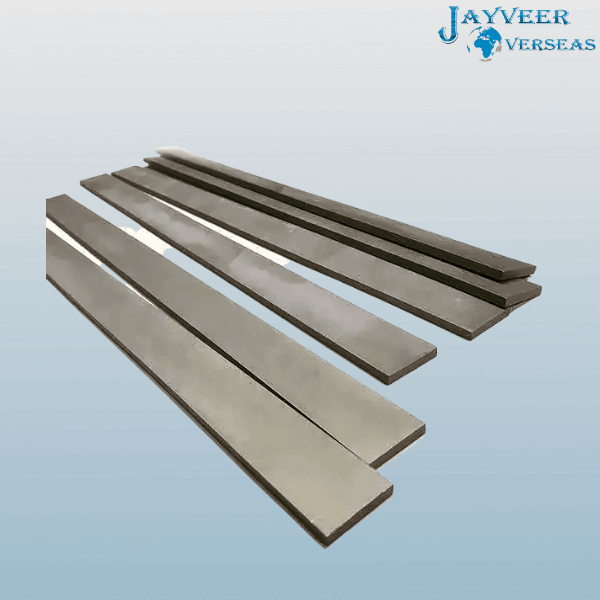

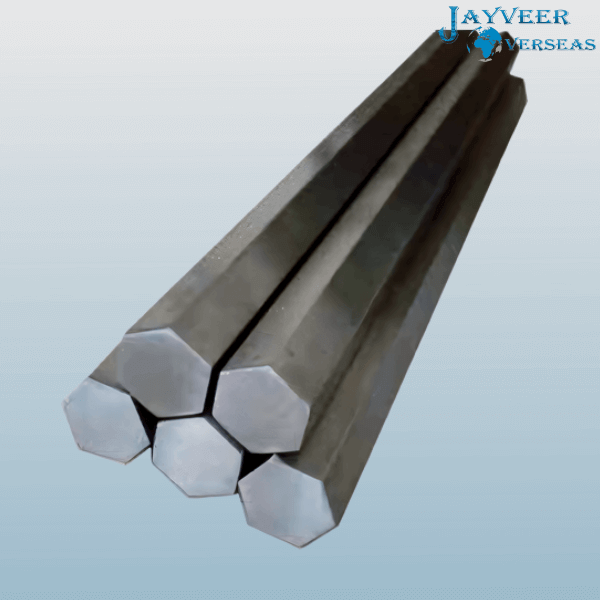

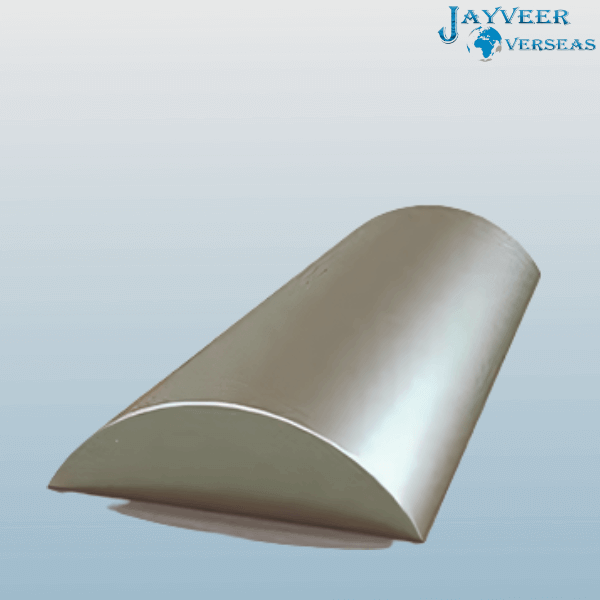

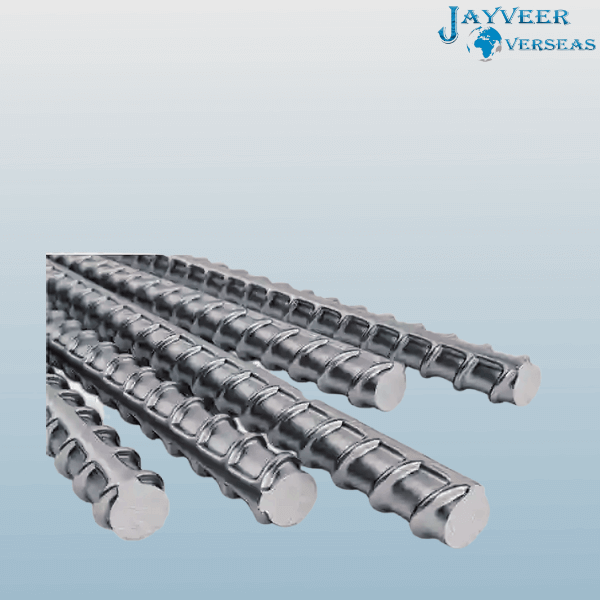

CU NI 90-10 Peeled Round Bar, ASTM B111 Type Cupro Nickel 90-10 Bright Bar, UNS C70600 Threaded Bar, Cupro Nickel 90-10 Hex Bar, CU NI Alloy 90-10 Square Bar, Cupro Nickel 90-10 Flat Bar, DIN 2.0872 Black Bar, CU NI 90-10 Rectangular Bar, ASME SB111 Cupro Nickel 90-10 Cold Drawn Bar.

Additionally, it is exceptionally versatile and weldable. The excellent mechanical characteristics of these bars maintain cryogenic temperatures. Acid, especially sulfuric acid, which is the deadliest, has little impact because of its strong resistance.

It provides consumers with a comparable level of resistance in the presence of nitric, phosphoric, and sulfuric acids. Niobium is a component of copper nickel 90/10 Round Bar. The product is stabilised against sensitisation by it. They are the ideal fusion of corrosion resistance, improved mechanical characteristics, and simplicity of production. These fittings include both nickel and molybdenum in their chemical makeup. These round bars are available in various size ranges varying from 14mm to 300mm. The thickness of these bars also ranges from 50mm to 6000mm. Because of its strength, it can withstand exposure to temperatures much beyond 1200 degrees Fahrenheit for extended periods without suffering any harm. the density of these round bars is 0.323 lb/in3 at 68 degrees Fahrenheit. The melting point of these rods is also 2260 Fahrenheit.

Given that it provides a lasting service, it serves as a value proposition for its end consumers. Furthermore, it exhibits resistance to intergranular corrosion. As the carbon and nitrogen are bound together as carbides or nitrides, these fittings prevent the development of chromium carbides. The finest nickel alloys are used to create these round bars. These CU NI 90-10 Round Bars serve primarily as a connector amid the pipes. They can also be plugged into pressure valves as a means of resistance. These are highly sought after for several large-scale industrial uses. The proper quantity of copper and nickel alloy used during the manufacturing of Cupro Nickel 90/10 Bar results in a superior-quality final product. Due to the product’s outstanding quality, demand has increased significantly.

ASTM B111 Cupro Nickel 90-10 Hot Rolled Bar Stockist, UNS C70600 Half Round Bar Supplier, Werkstoff Nr. 2.0872 Deformed Bar Supplier, Cupro Nickel 90-10 Flat Bar Exporter, UNS C70600 Hexagonal Bar Exporter, WRN 2.0872 Polished Bar Manufacturer, Copper Nickel 90-10 Triangle Bar Stockist.

Specification:- CU NI 90-10 Round Bar

| Specifications | ASTM B111 / A479, ASME SB111 / A479 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars | 18mm – 57mm (11/16″ to 2-3/4″) |

| Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

| Flat Bars | 1/2” to 10” in thickness range of 2mm to 150mm, |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

Equivalent Grade :- CU NI 90-10 Round Bar

| STANDARD | UNS | WNR. | EN | AFNOR |

| Cupro Nickel 90/10 | C70600 | 2.0872 | NiCr20CuMo | Z2NCUD31-20AZ |

Chemical Composition :- CU NI 90-10 Round Bar

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cupro Nickel 90/10 | 88.6 | 1.0 max | 0.05 max | 9 - 11 max | 1.8 max | 1 max |

Mechanical Properties :- CU NI 90-10 Round Bar

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Dimensions :- CU NI 90-10 Round Bar

| Diameter or Width (mm) | Weight per meter | Sectional Area | Perimeter | |||

| Square (kg) | Round (kg) | Square (cm²) | Round (cm²) | Square (cm) | Round (cm) | |

| 5.0 | 0.20 | 0.15 | 0.25 | 0.20 | 2.0 | 1.57 |

| 5.5 | 0.24 | 0.19 | 0.30 | 0.24 | 2.2 | 1.78 |

| 6.0 | 0.28 | 0.22 | 0.36 | 0.28 | 2.4 | 1.88 |

| 7.0 | 0.38 | 0.30 | 0.49 | 0.38 | 2.8 | 2.20 |

| 8.0 | 0.50 | 0.39 | 0.64 | 0.50 | 3.2 | 2.51 |

| 9.0 | 0.64 | 0.50 | 0.81 | 0.64 | 3.6 | 2.83 |

| 10 | 0.73 | 0.63 | 1.00 | 0.79 | 4.0 | 3.14 |

| 11 | 0.95 | 0.75 | 1.21 | 0.95 | 4.4 | 3.46 |

| 12 | 1.13 | 0.89 | 1.44 | 1.13 | 4.8 | 3.77 |

| 14 | 1.54 | 1.21 | 1.96 | 1.54 | 5.6 | 4.40 |

| 16 | 2.01 | 1.58 | 2.56 | 2.01 | 6.4 | 5.03 |

| 18 | 2.54 | 2.00 | 3.24 | 2.54 | 7.2 | 5.65 |

| 20 | 3.14 | 2.47 | 4.00 | 3.14 | 8.0 | 6.28 |

| 22 | 3.80 | 2.98 | 4.84 | 3.80 | 8.8 | 6.91 |

| 25 | 4.91 | 3.85 | 6.25 | 4.91 | 10.0 | 7.85 |

| 28 | 6.15 | 4.83 | 7.84 | 6.16 | 11.2 | 8.80 |

| 32 | 8.04 | 6.31 | 10.24 | 8.04 | 12.8 | 10.05 |

| 36 | 10.17 | 7.99 | 12.96 | 10.18 | 14.4 | 11.31 |

| 40 | 12.56 | 9.86 | 16.00 | 12.57 | 16.0 | 12.57 |

| 45 | 15.90 | 12.49 | 20.25 | 15.90 | 18.0 | 14.14 |

| 50 | 19.62 | 15.41 | 25.00 | 19.64 | 20.0 | 15.71 |

| 56 | 24.62 | 19.34 | 31.36 | 24.63 | 22.4 | 17.59 |

| 63 | 31.16 | 24.47 | 36.69 | 31.17 | 25.2 | 19.79 |

| 71 | 39.57 | 31.08 | 50.41 | 39.59 | 28.4 | 22.31 |

| 80 | 50.24 | 39.46 | 64.00 | 50.27 | 32.0 | 25.13 |

Types :- CU NI 90-10 Round Bar

weight chart :- CU NI 90-10 Round Bar

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3" | 10.900 | 35.762 |

| 1/8" | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4" | 12.800 | 41.996 |

| 5/32" | 0.029 | 0.095 | 7/8" | 0.926 | 3.038 | 3-1/2" | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4" | 17.001 | 55.780 |

| 3/16" | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4" | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1" | 1.210 | 3.970 | 4-1/4" | 21.908 | 72.249 |

| 7/32" | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2" | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4" | 27.366 | 90.249 |

| 1/4" | 0.076 | 0.249 | 1-1/8" | 1.534 | 5.033 | 5" | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2" | 36.690 | 121.000 |

| 5/16" | 0.118 | 0.387 | 1-1/4" | 1.924 | 6.349 | 6" | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2" | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8" | 2.303 | 7.550 | 7" | 59.432 | 196.000 |

| 3/8" | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2" | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8" | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10" | 121.048 | 397.140 |

| 7/16" | 0.232 | 0.761 | 1-1/2" | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2" | 0.303 | 0.994 | 1-5/8" | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4" | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16" | 0.383 | 1.256 | 1-7/8" | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8" | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2" | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8" | 5.475 | 17.963 | |||

| 11/16" | 0.573 | 1.880 | 2-1/4" | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4" | 0.682 | 2.237 | 2-3/8" | 6.838 | 22.435 | |||

| 2-1/2" | 7.576 | 24.856 | ||||||

| 2-5/8" | 8.354 | 27.409 | ||||||

| 2-3/4" | 9.169 | 30.083 |

available stocks :- CU NI 90-10 Round Bar

Price List :- CU NI 90-10 Round Bar

| Round Bars | US $1000-2500 / Ton |

| Square Bars | US $1000-2500 / Ton |

| Flat Bars | US $1.5-4.5 / Kilogram |

| Threaded Bars | US $1800-2300 / Ton |

| Hollow Bars | US $1550-2400 / Ton |

| Hexagonal Bars | US $1800-2300 / Ton |

| Triangular Bars | US $1300-2600 / Metric Ton |

industries we serve :

- Biodiesel and ethanol plants and tanks

- Palm oil and wine storage tanks

- Bridges, flood gates, and sluice gates

- Washers and paper machine parts

- Pulp and paper mill equipment

- Mixers and agitators

- Architectural applications

- Waste water handling systems

- Ethanol production components

- Desalination system chambers and evaporators

- External absorber and outlet duct reinforcements

- Chemical process pressure vessels, piping and heat exchangers

- Pressure vessels, heat exchangers, tanks, piping systems and tankers

- Hydrogen peroxide bleaching reactors, digesters, and white liquor storage tanks

Packaging Used by us :

We ship our stainless steel metal products in industry leading packaging designed to ensure your order reaches its destination safely. We offer multiple packaging options to meet your specific requirements. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging. We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

- Shrink-wrapped

- Carton boxes

- Wooden pallets

- Wooden boxes

- Wooden crates

Quality and tests Done by us :

- Positive material recognition

- Mechanical examining like tensile, Elongation and reduction of area.

- Large-scale test

- Chemical examination-Spectro analysis

- Firmness test

- Pitting protection test

- Hydrogen-effected cracking test approved by NACE TM0284

- Small tests

- X-ray test

- Impact analysis

- Eddy current examining

- Hydrostatic analysis

- Prompt test

- Sulfide stress corrosion test approved by NACE TM 0177

- Curve test

-

Related Search Queries

-

City We Supply

-

Country We Export